Note: All data is mock and does not represent real production figures. Confidential details have been removed.

Volkswagen Group

Orchestrating Complexity: VW Supply Chain

Control Center

Product Format: Web application (Responsive)

Project Year: 2022 – Present

Business Partner: VW Group Procurement

What if enterprise tools were as intuitive as the apps we use every day — no matter how complex the workflow or data?

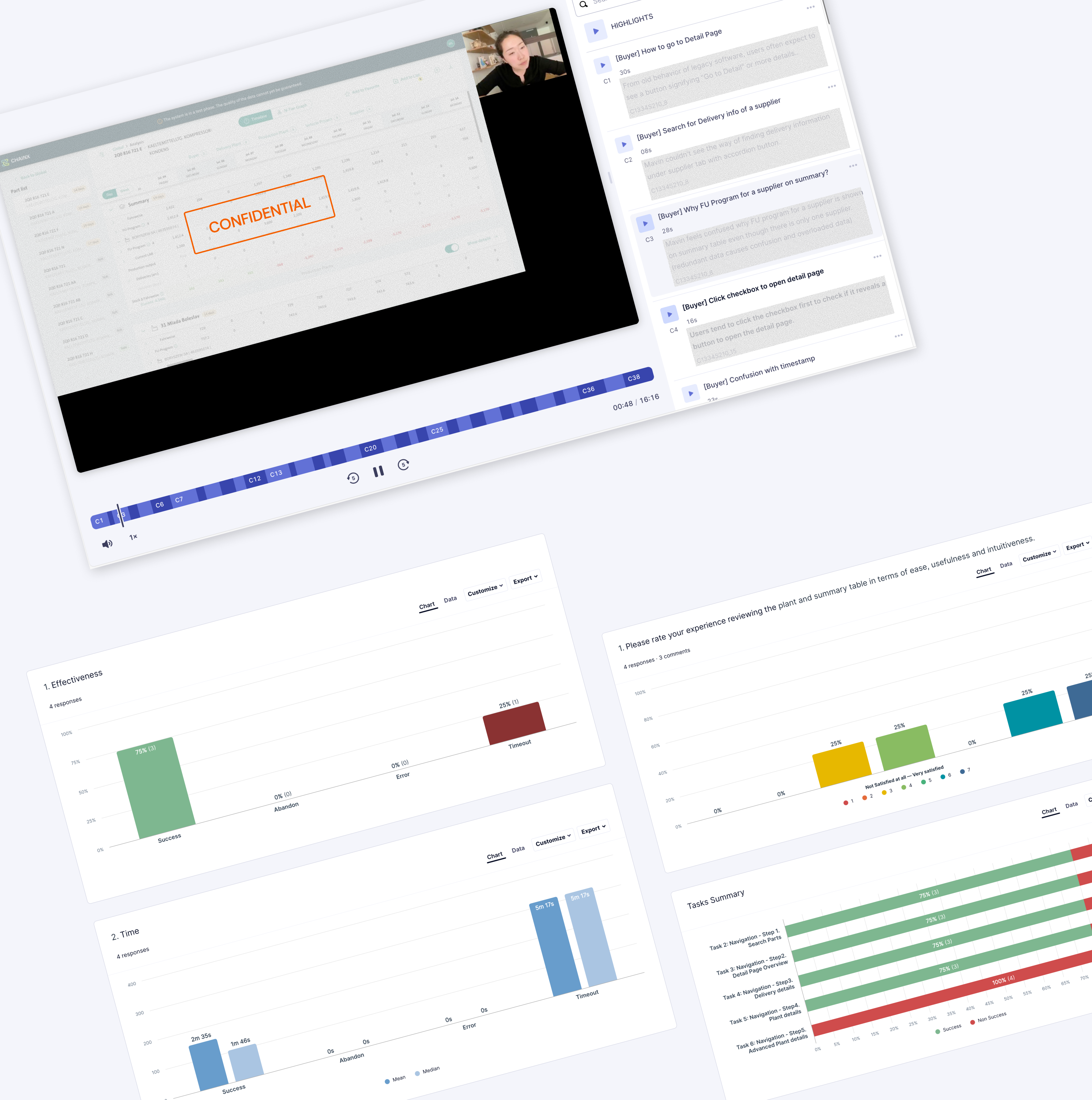

Field research & user workshop

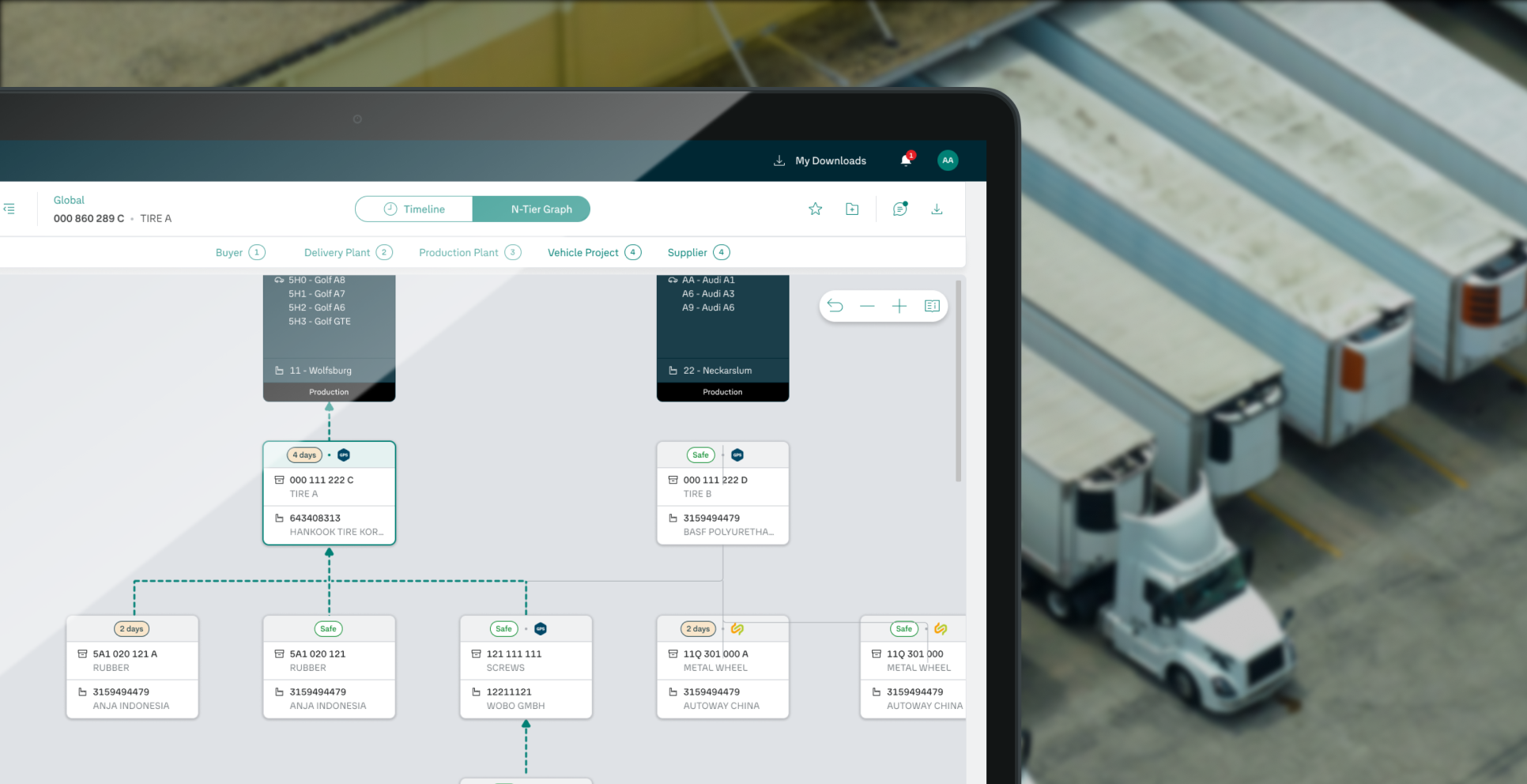

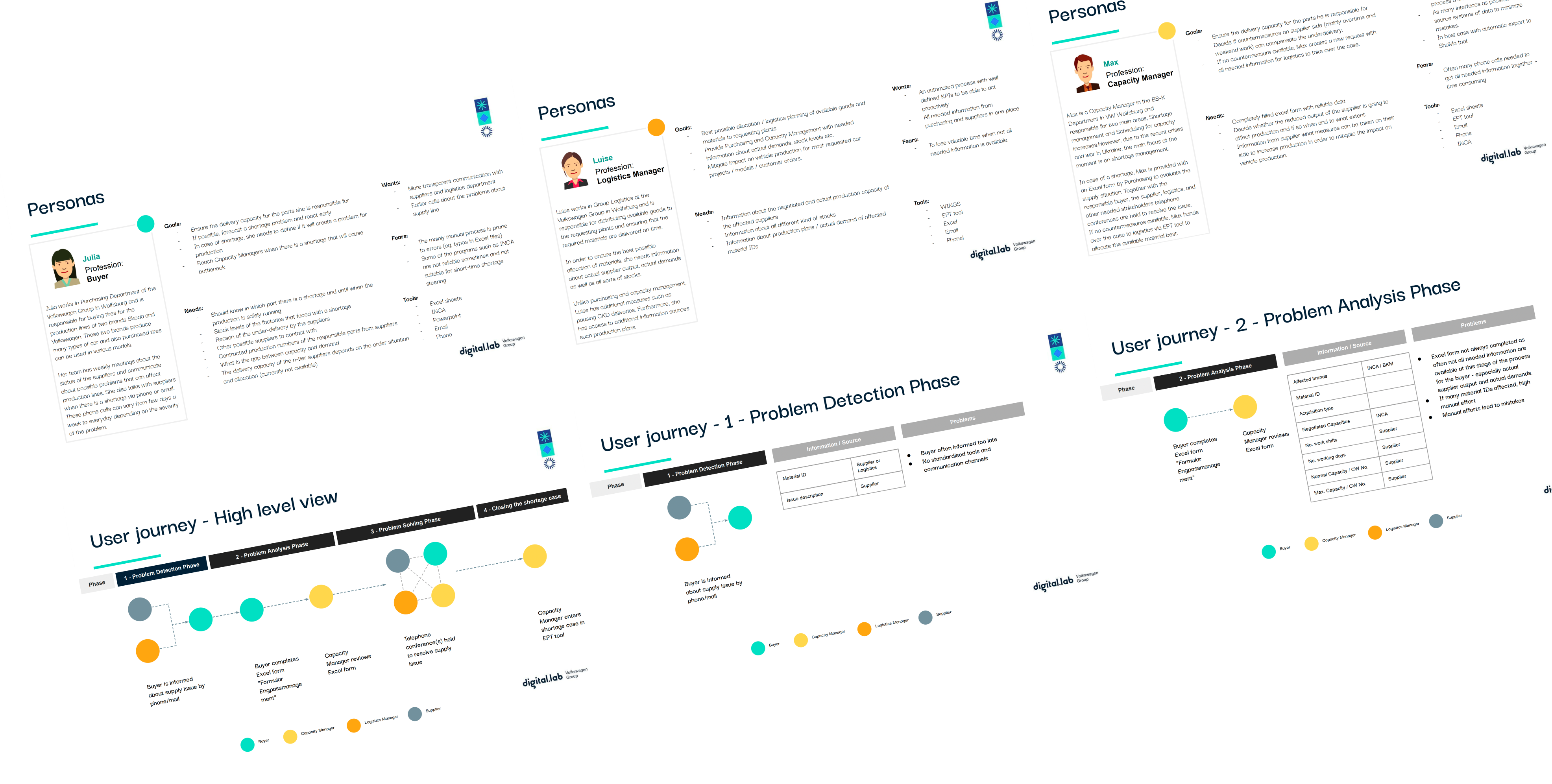

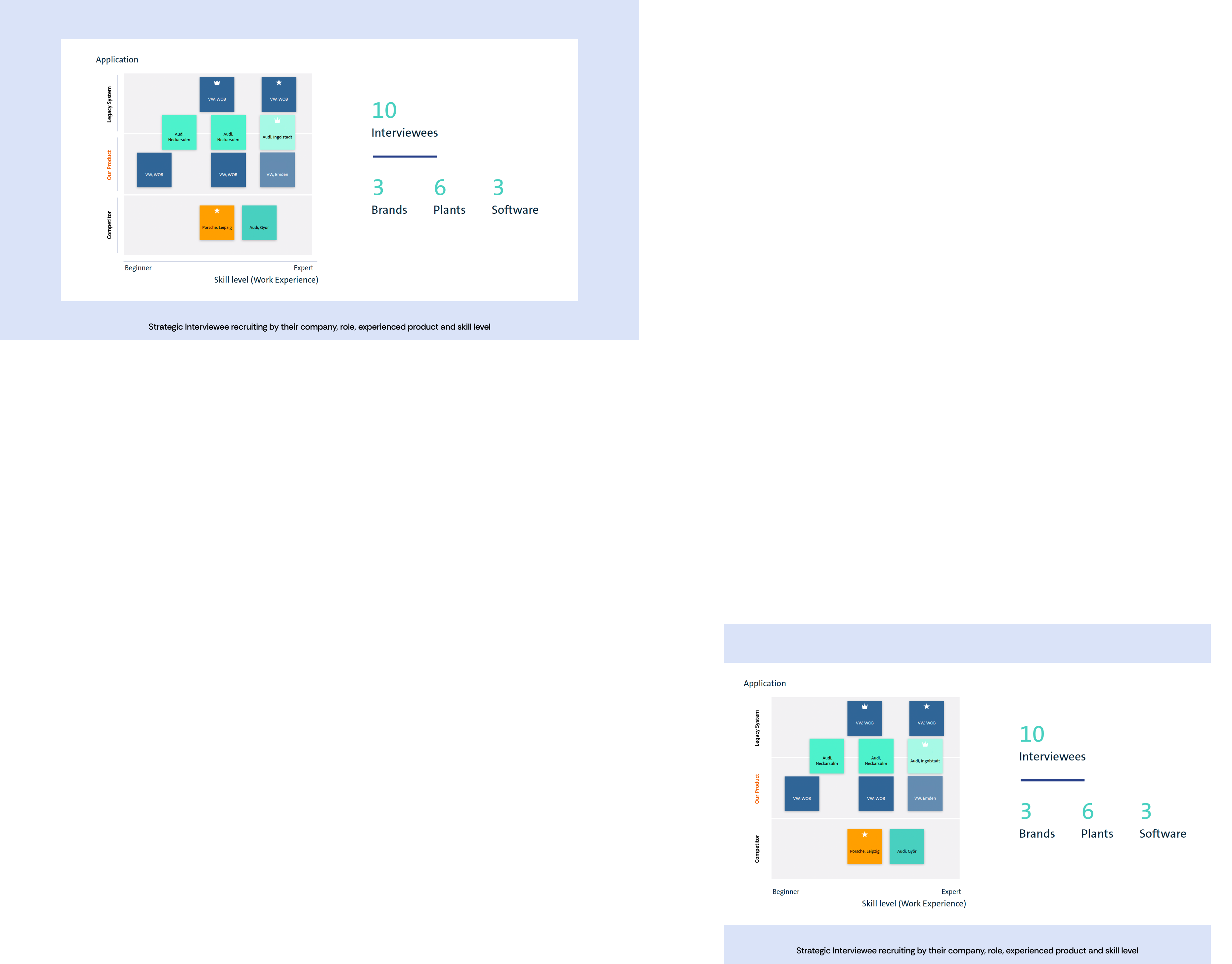

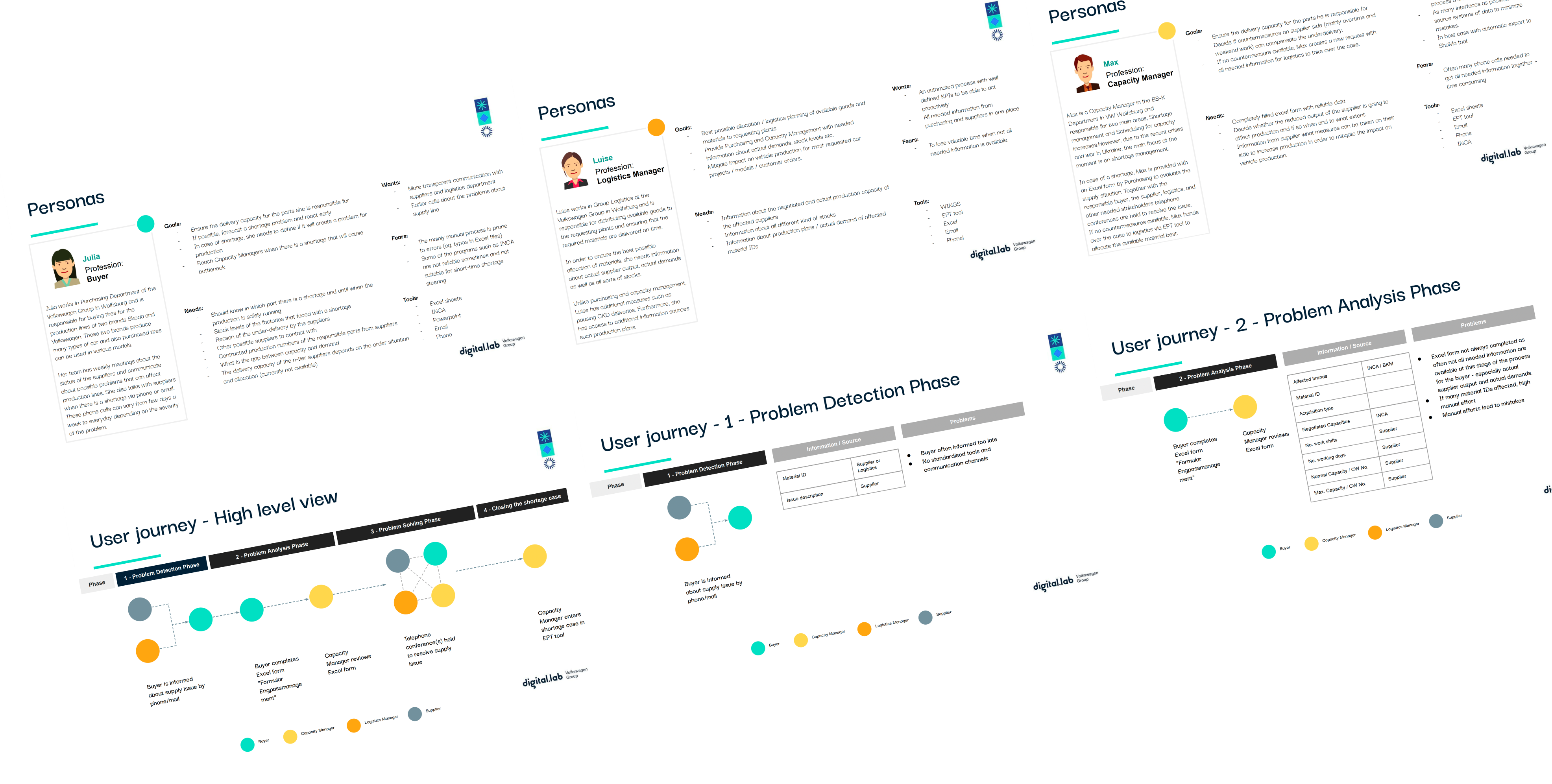

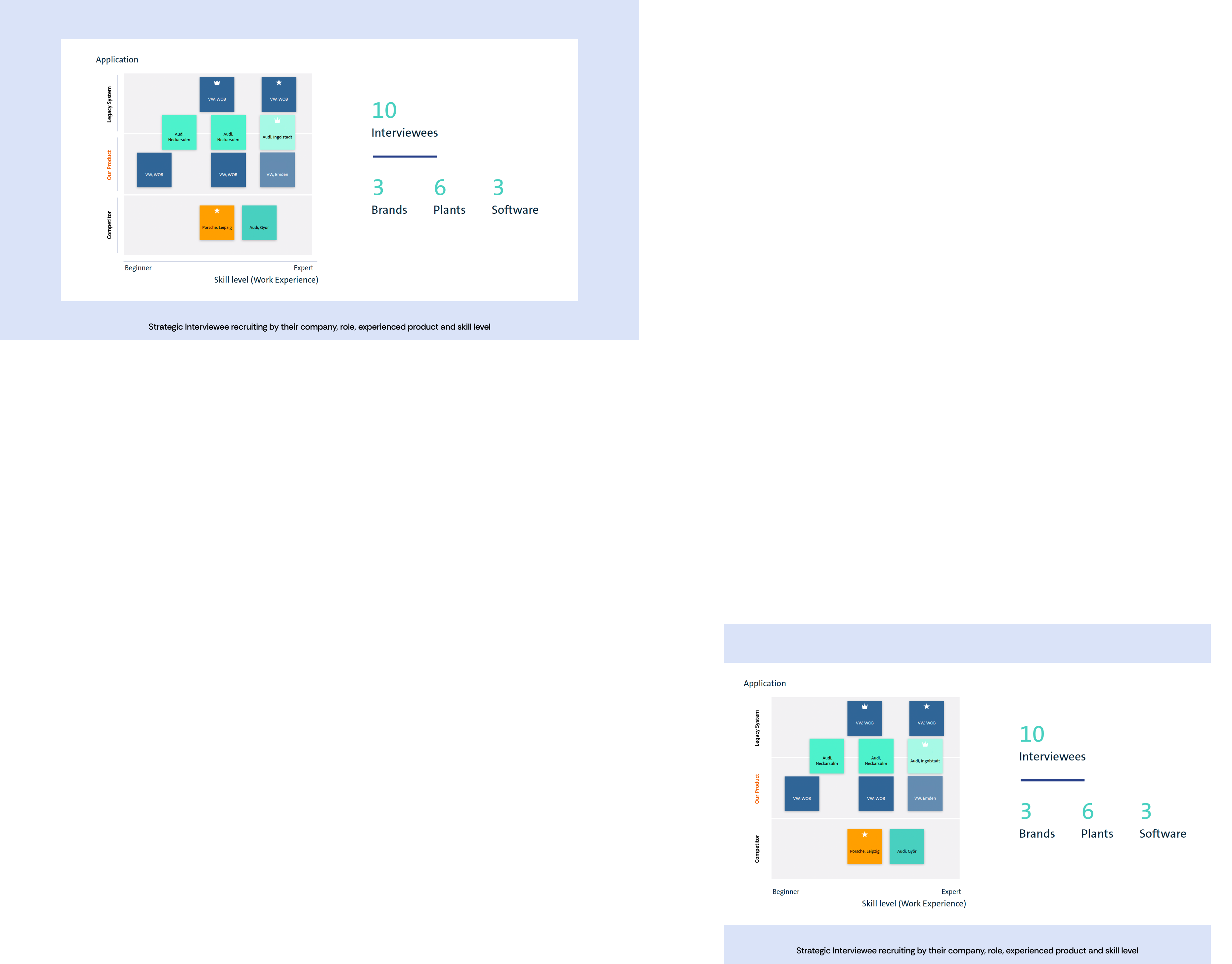

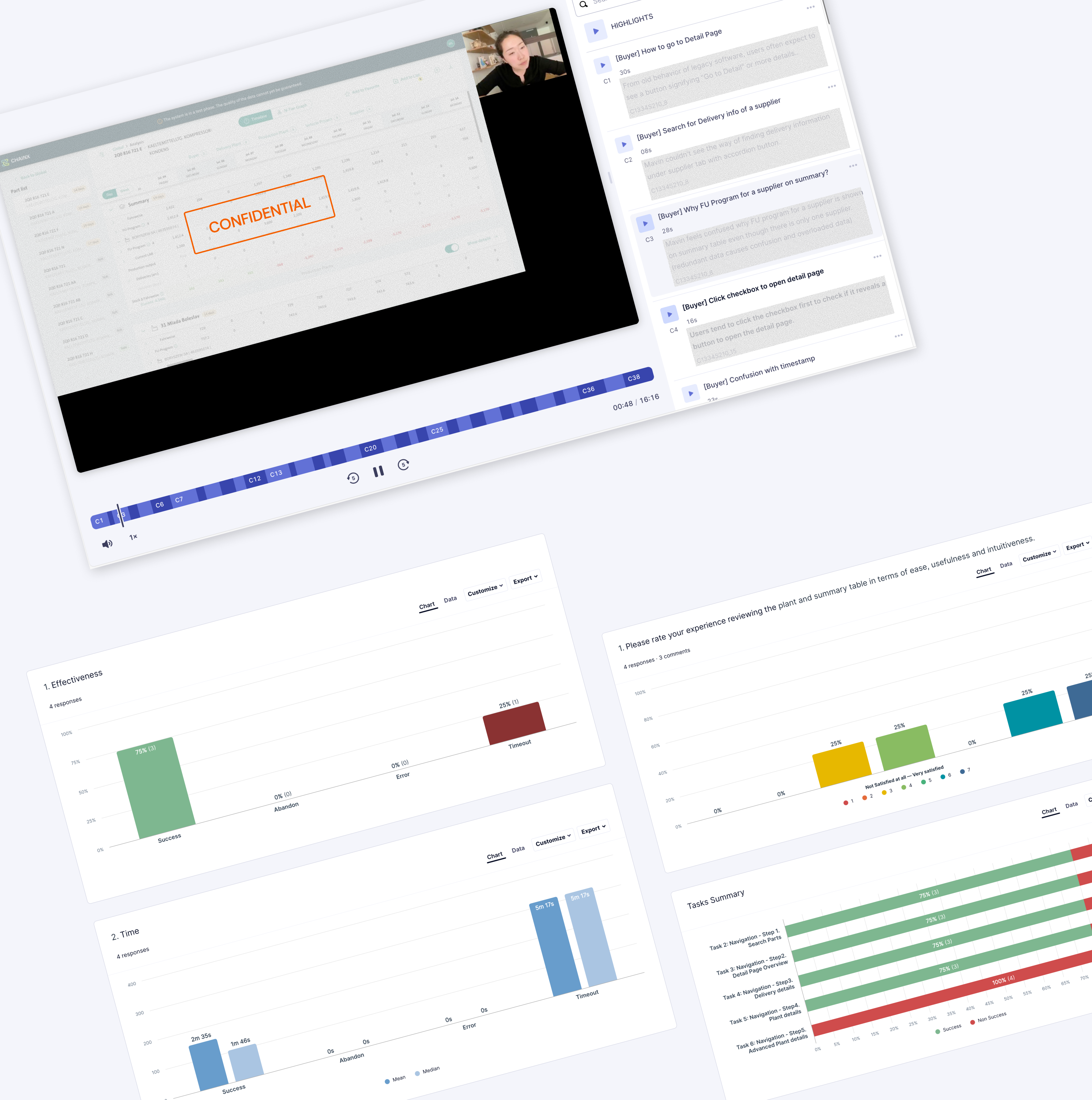

To gather diverse insights, we intentionally brought in 10 users from different environment and knowledge level.

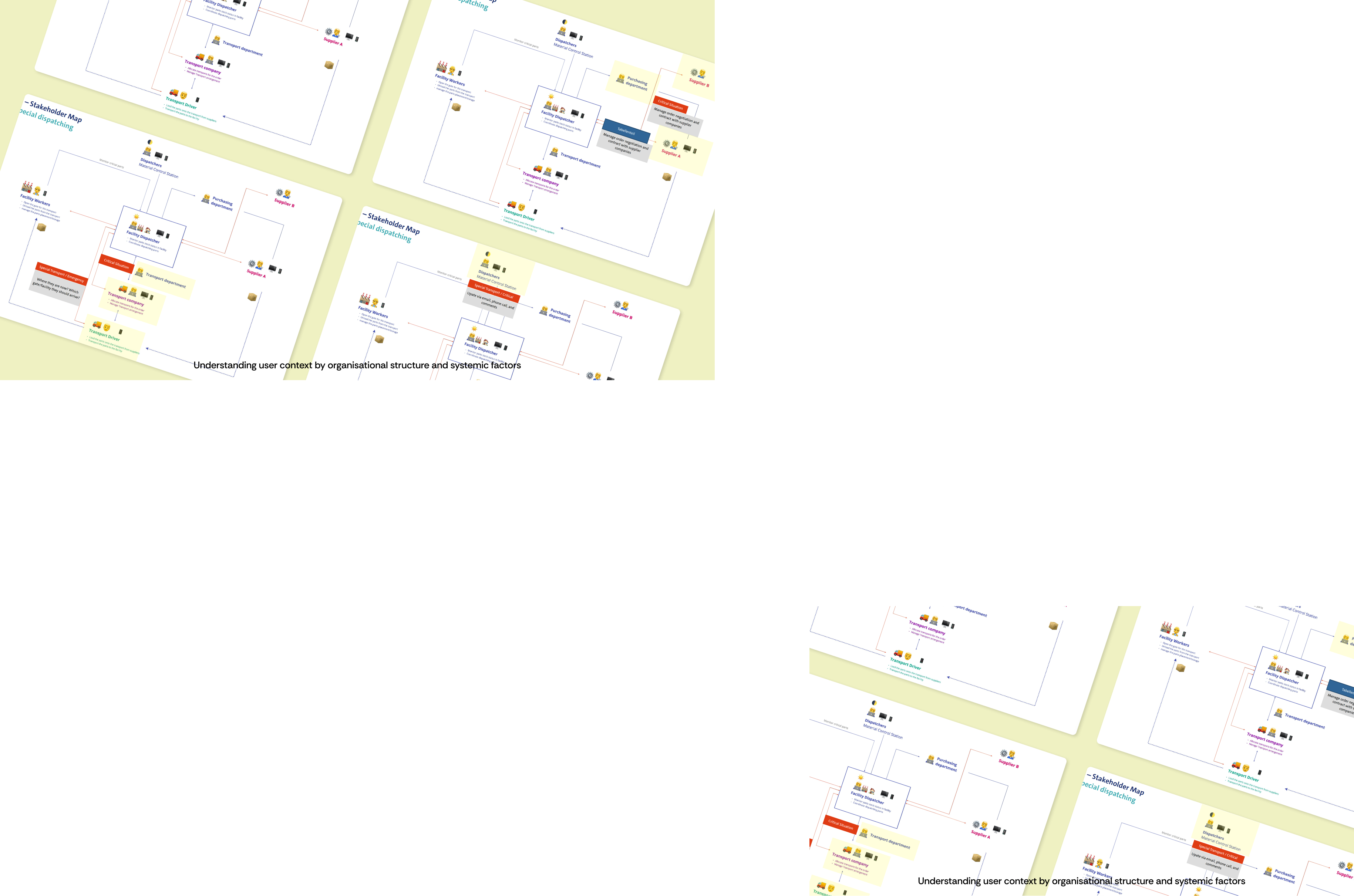

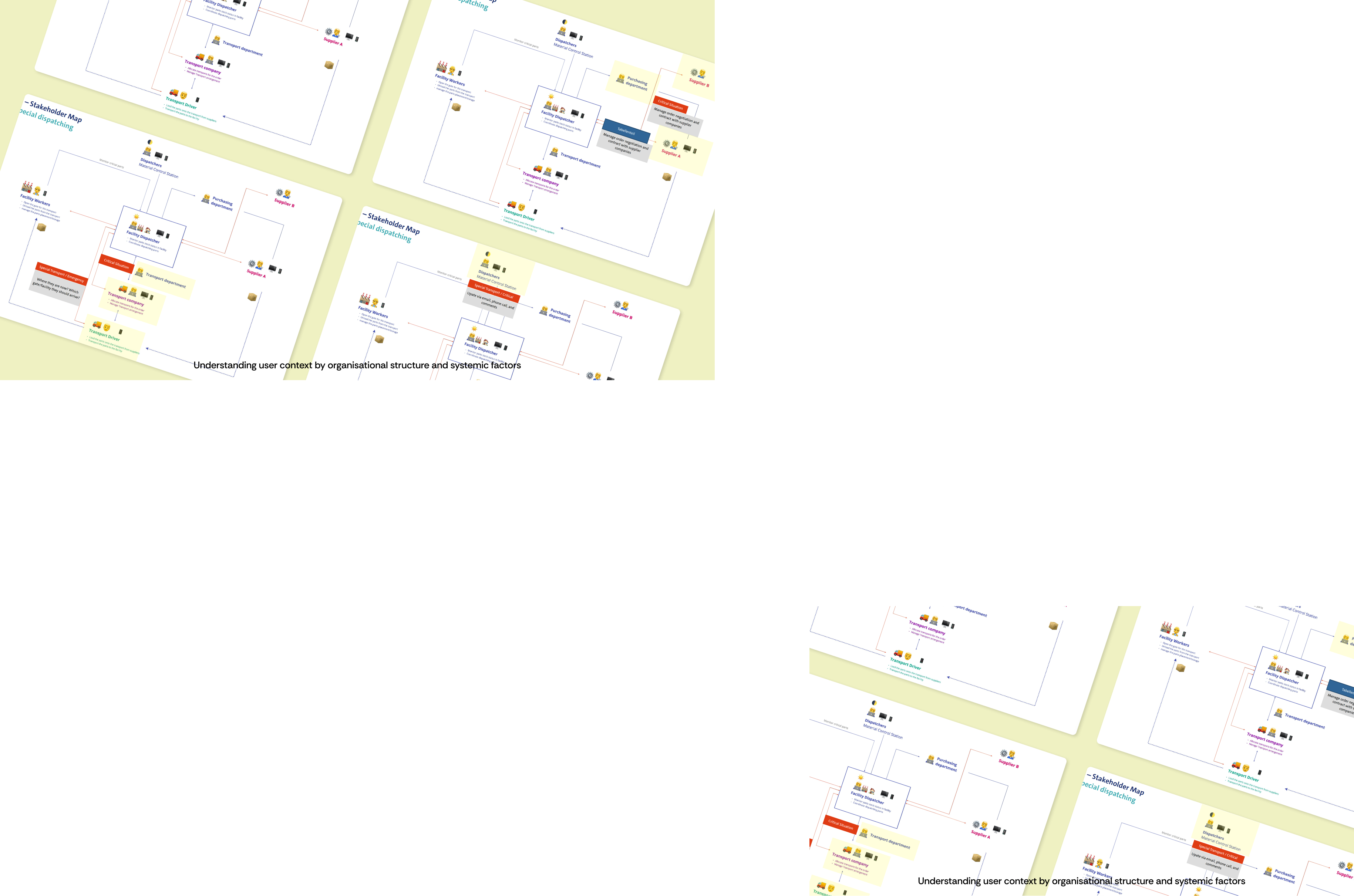

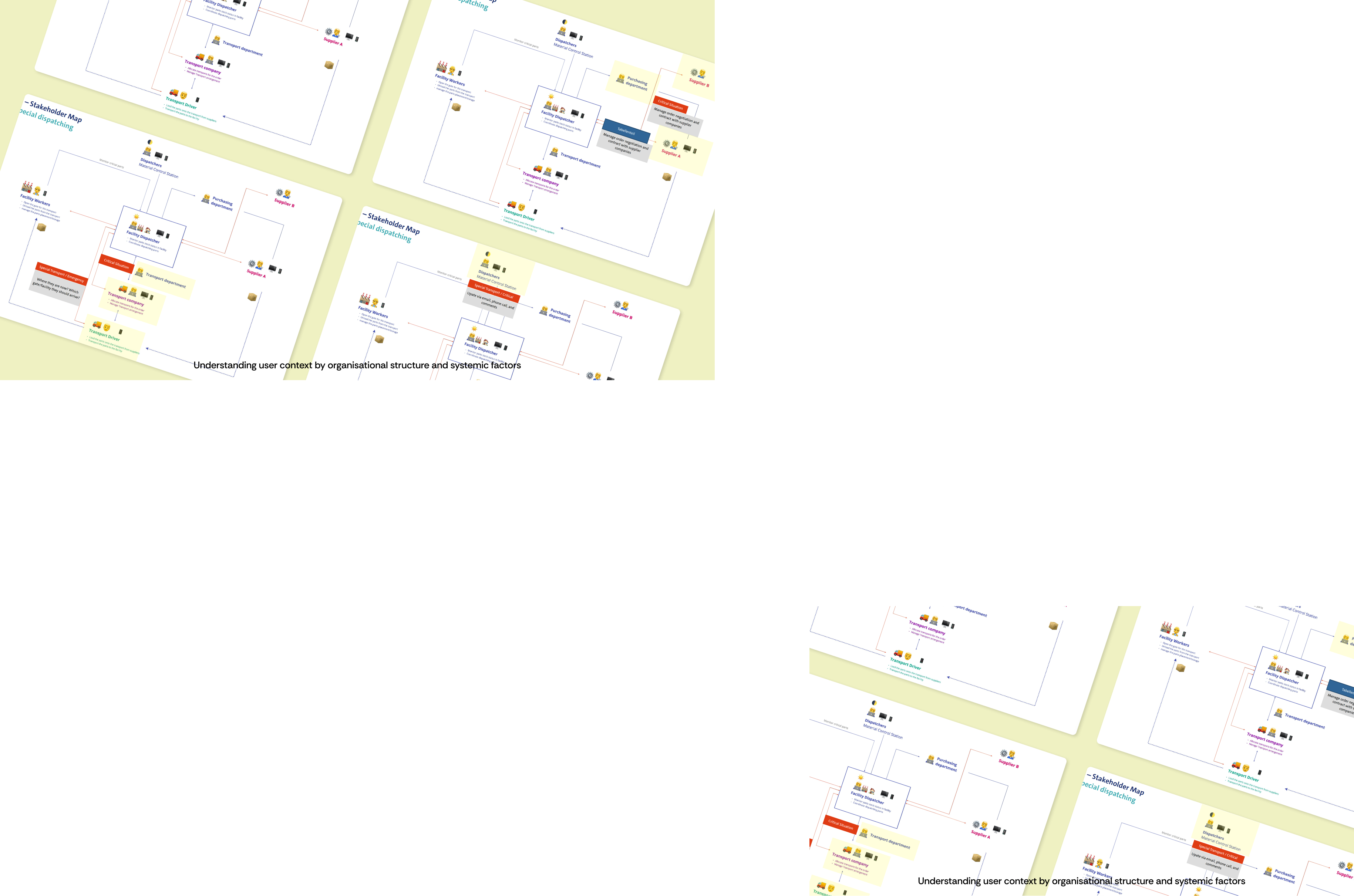

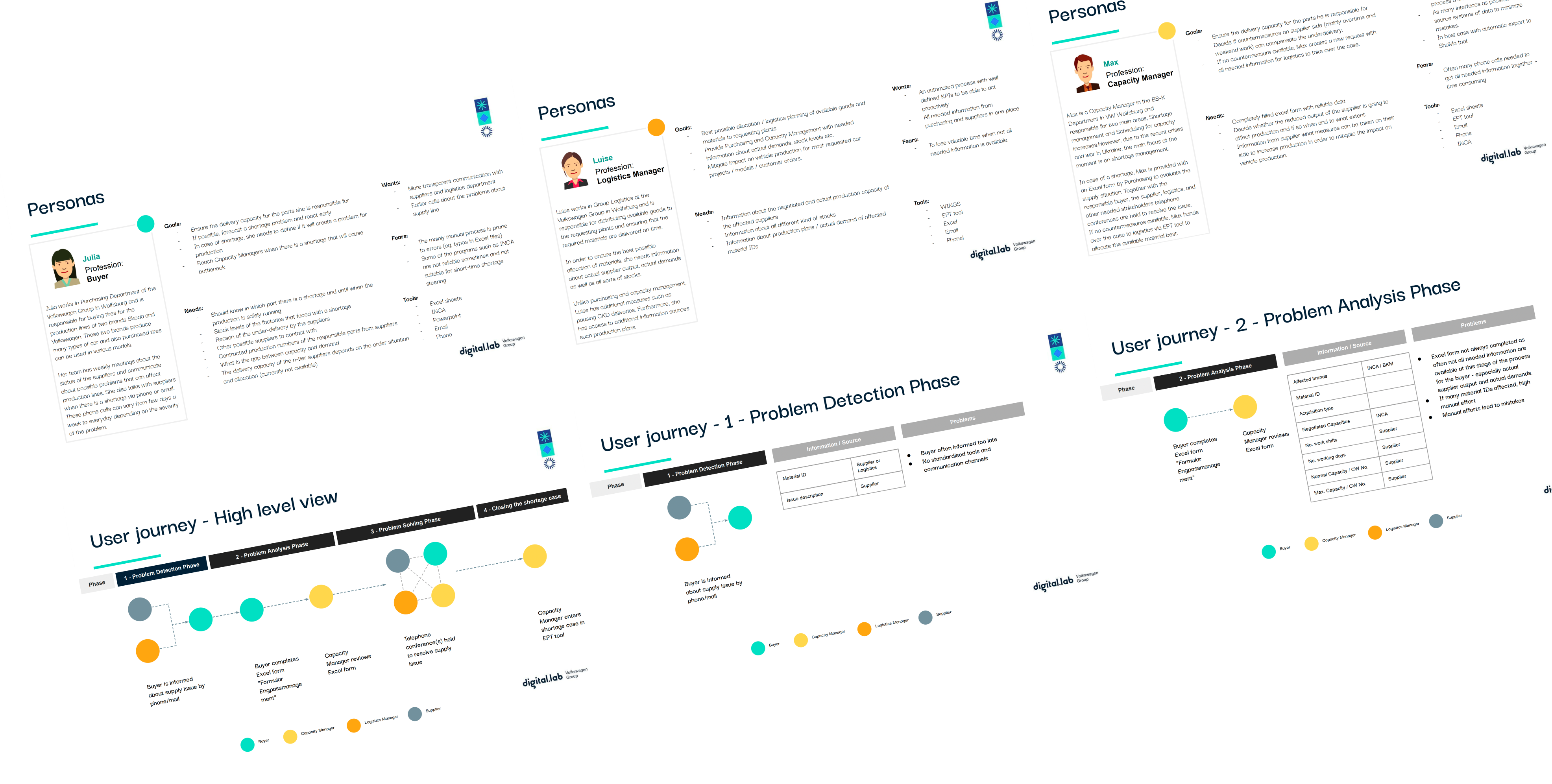

We asked multiple questions about their daily process and digital and physical touch points in identifying part situation and shadowed their daily work over three days. Afterwards, we sat down and mapped their work processes and visualised the stakeholder map in Miro.

Stakeholder mapping

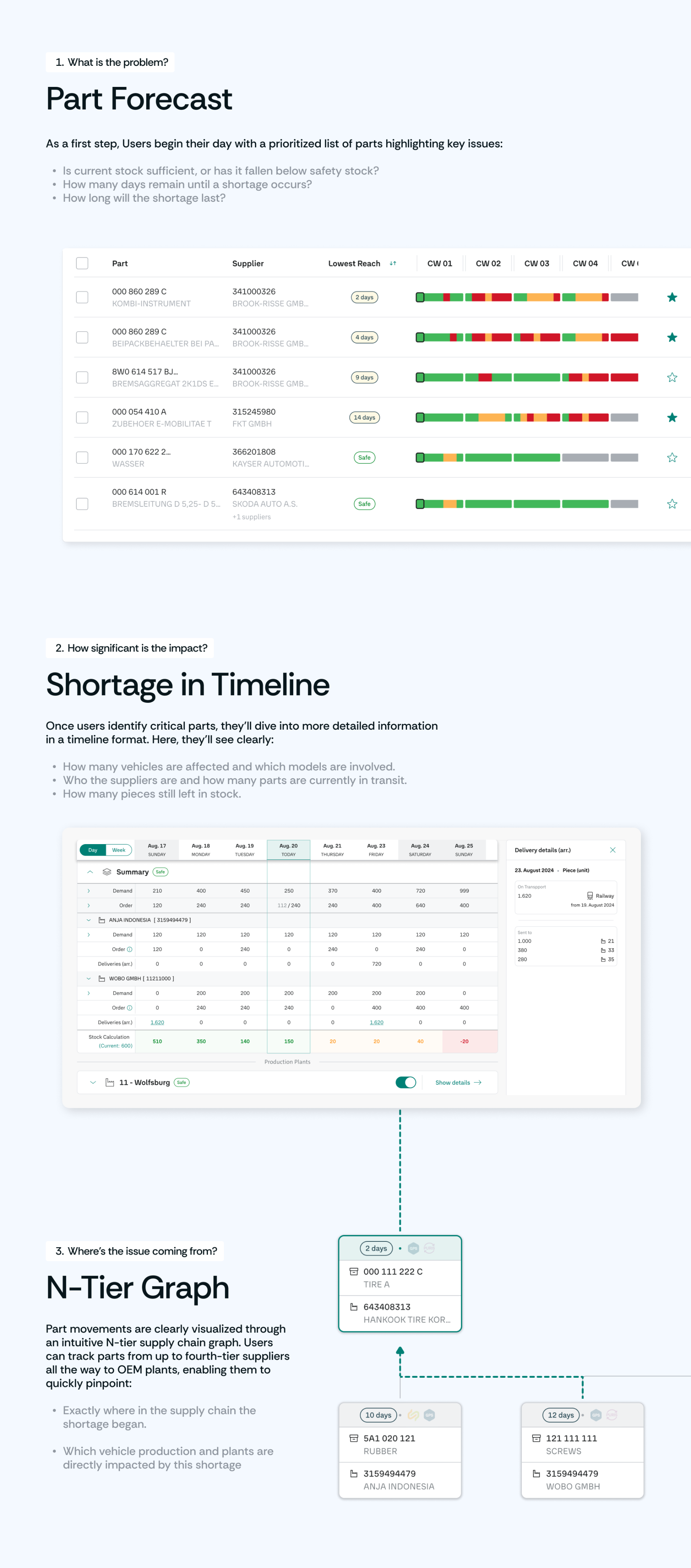

Focus Area: “Problem Detection”

Challenge & Opportunities

Challenge 1

Cognitive Overload: All information on one page creates distraction and prevents effective shortage identification

Challenge 2

Tool Carnivalism: Disconnected systems for shortage identification, problem solving, and reporting create silos and internal cannibalization

Challenge 3

Supply Chain Blind Spots: Missing external supplier information and tier relations obscure 80% of shortage root causes

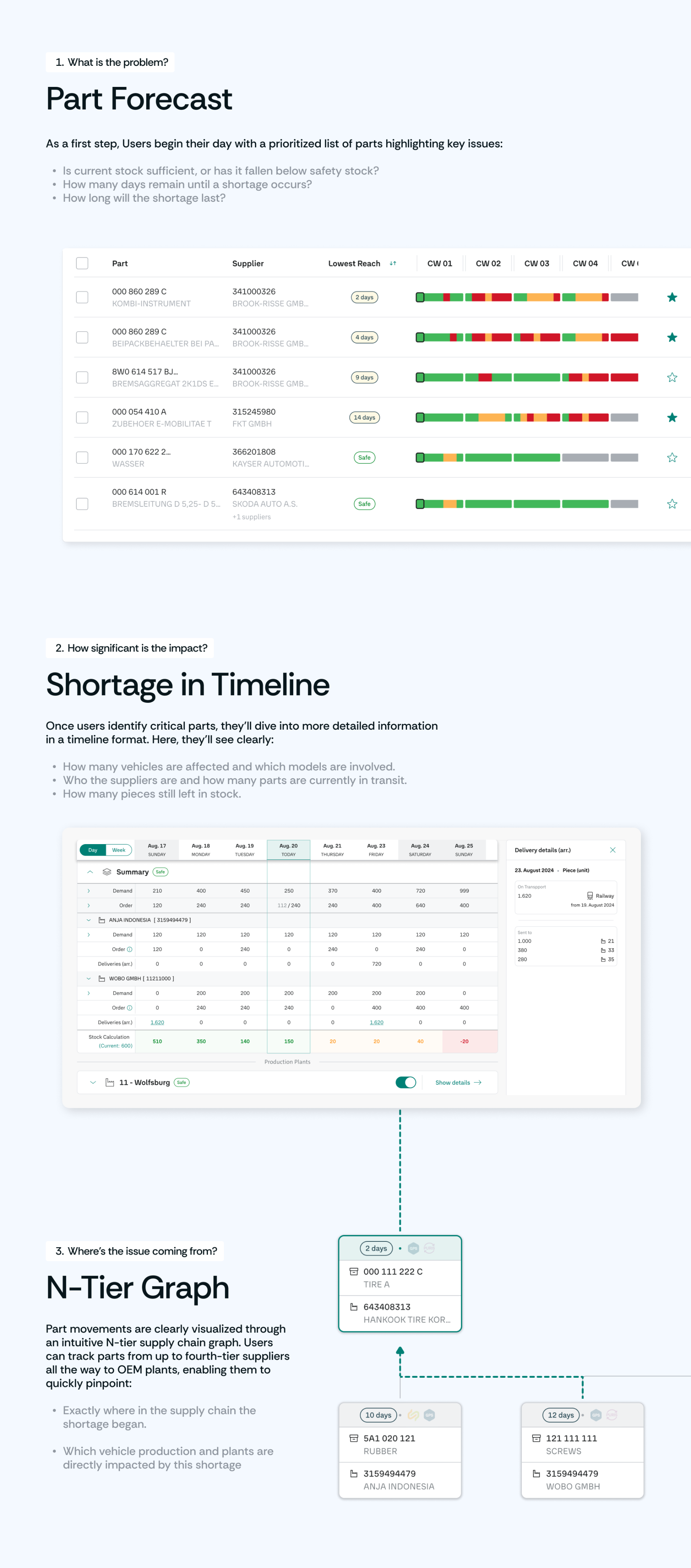

Opportunity 1

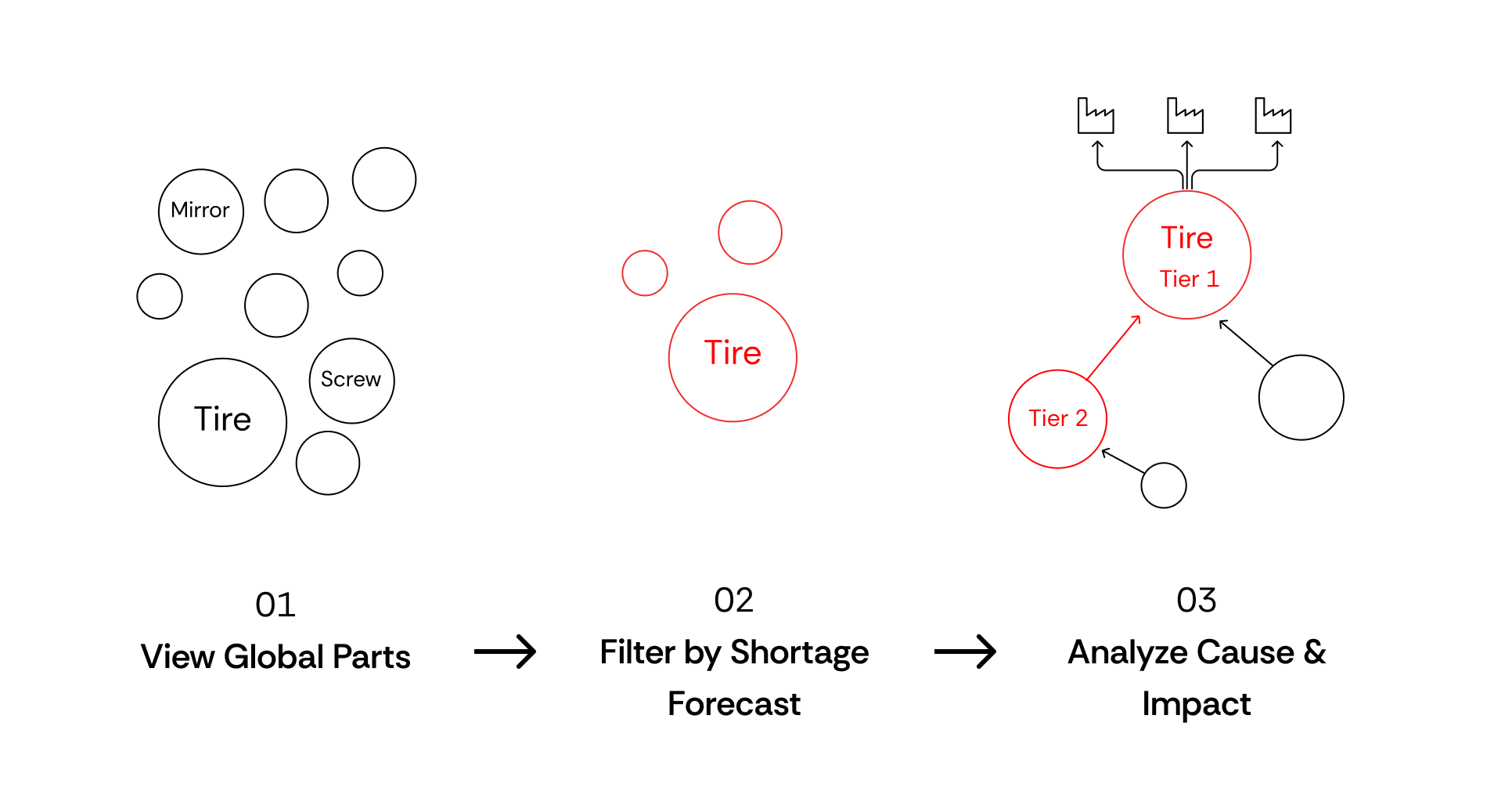

Staged Information Diet: Divide workflow into three digestible pages—Global overview, Part details, and Bottleneck management

Opportunity 2

Ecosystem Orchestration: Provide API bridges to specialized tools instead of building everything, enabling seamless cross-platform workflows

Opportunity 3

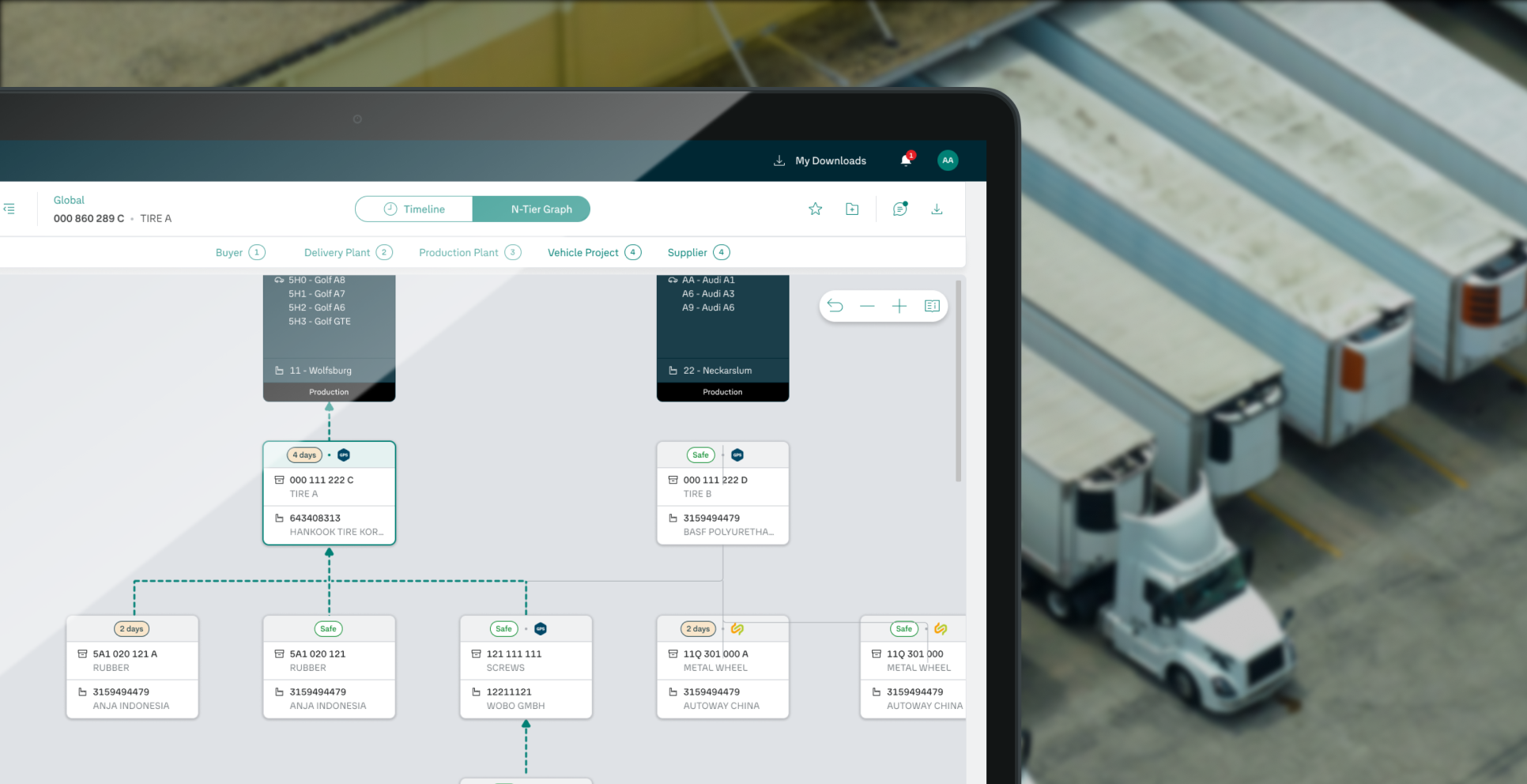

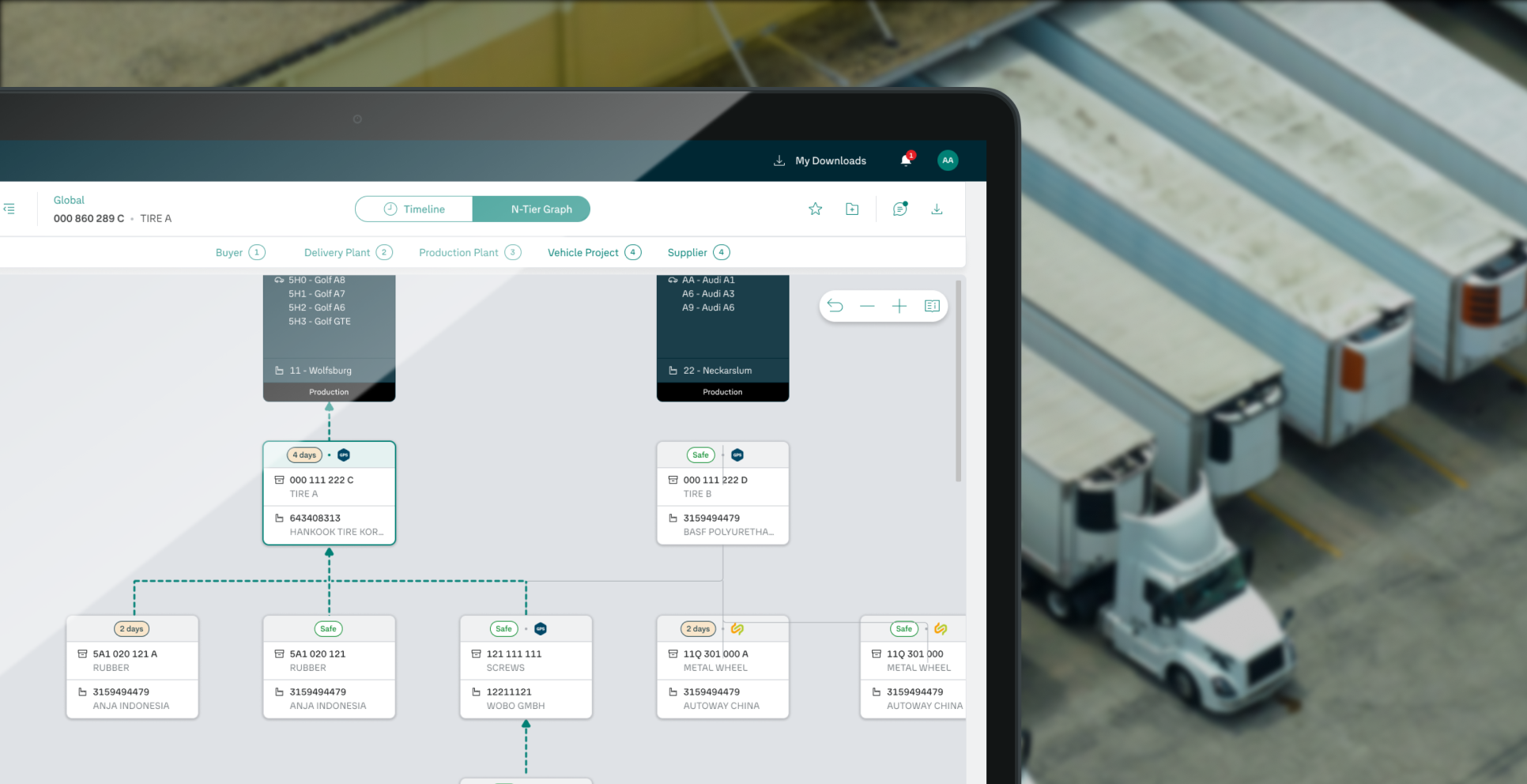

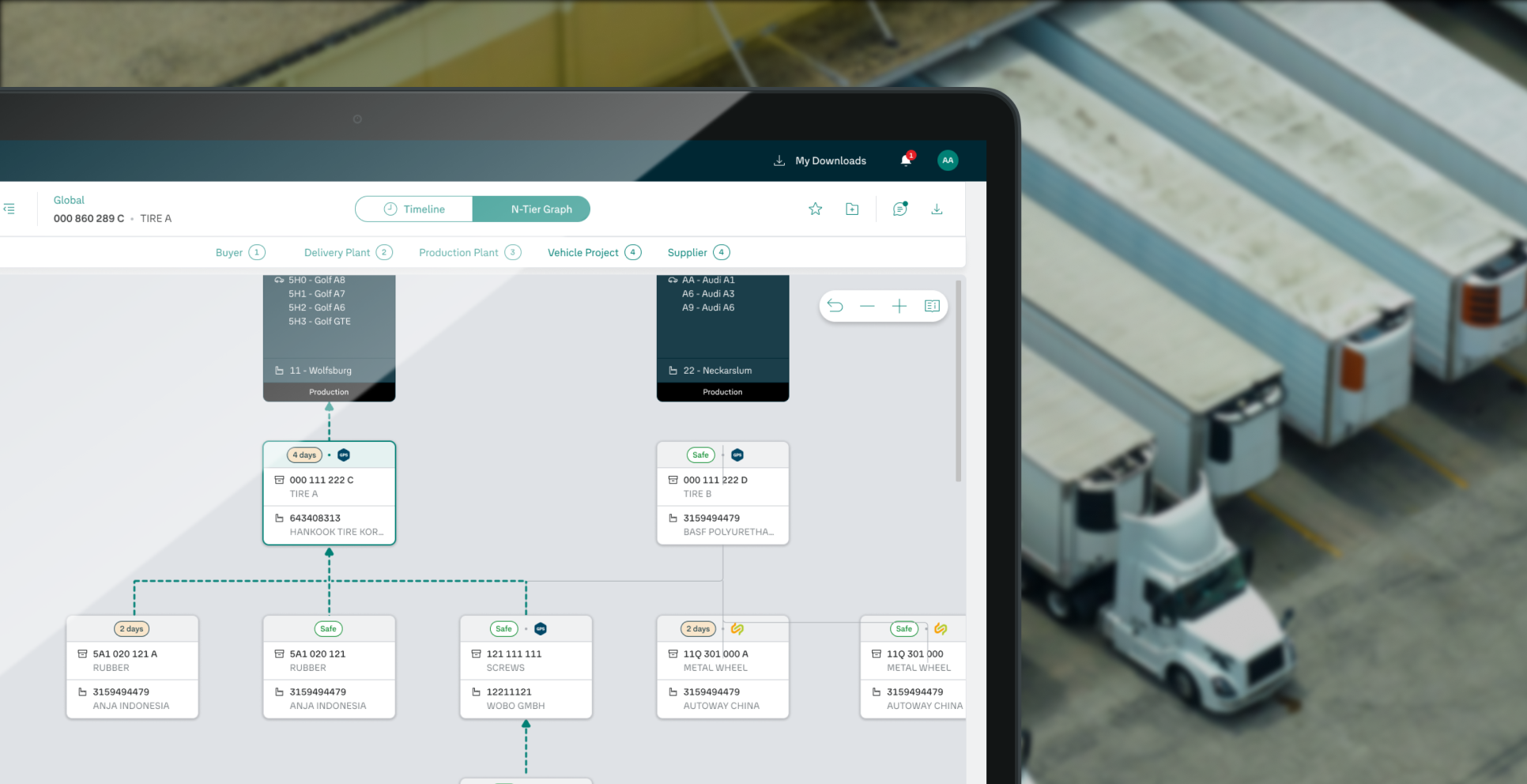

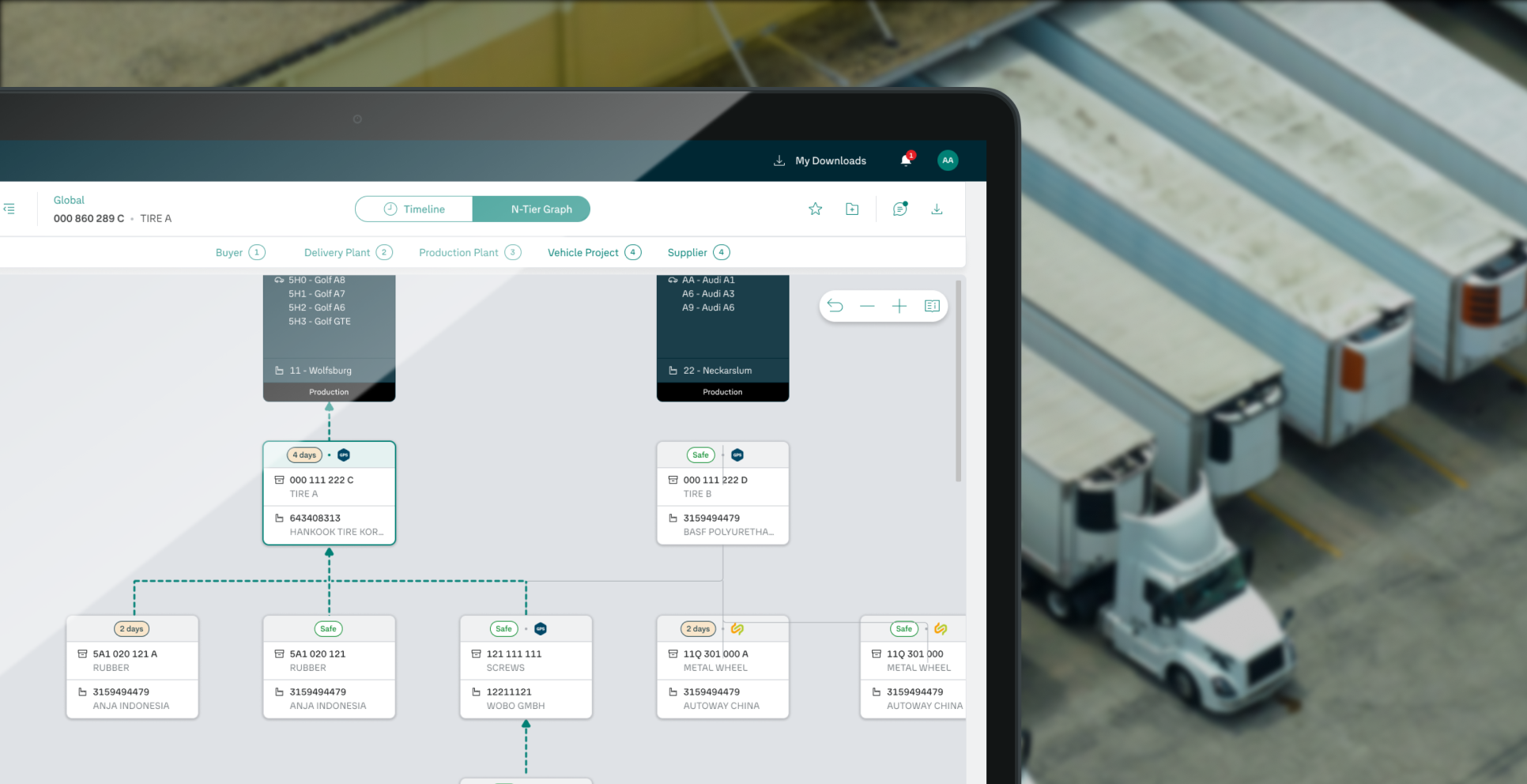

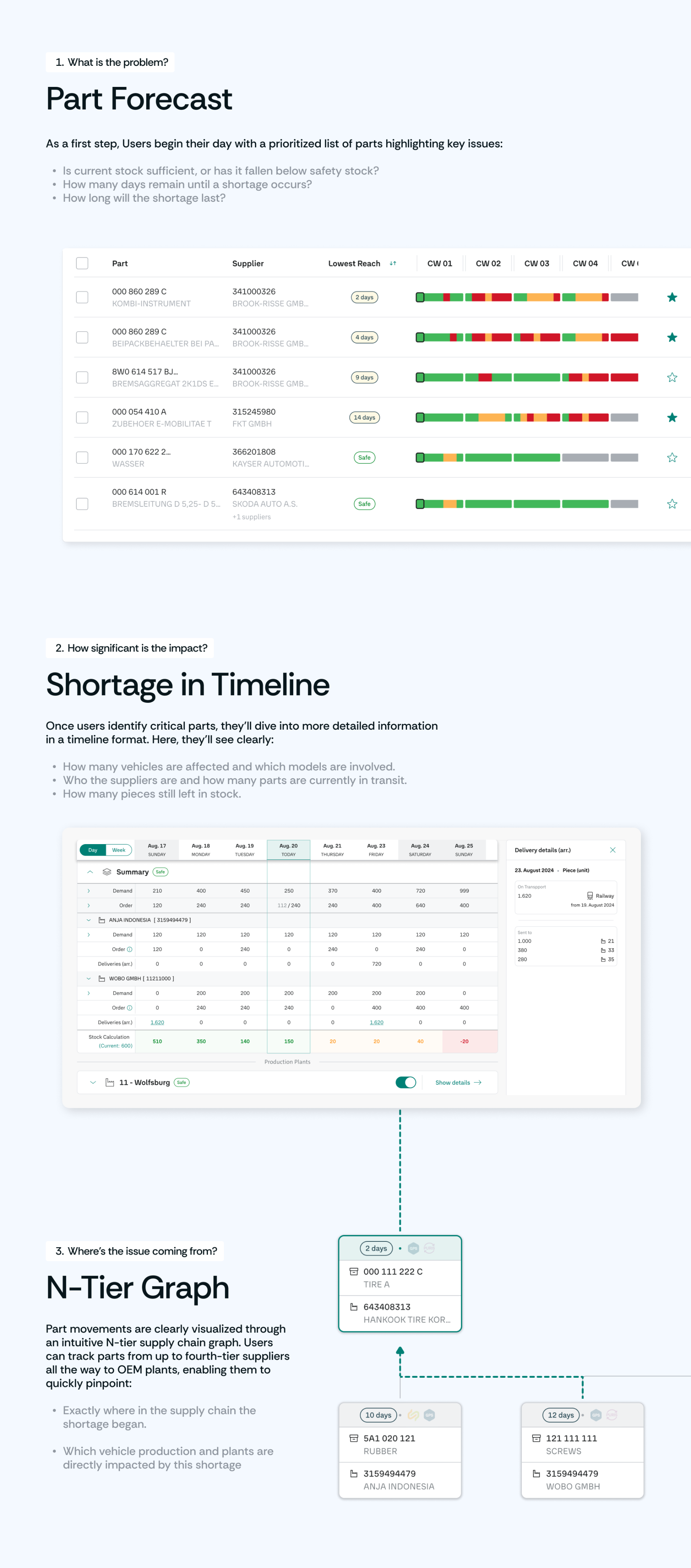

N-tier Graph: Use graph visualization to reveal hidden part-specific supply chain relationships with BOM data

Figma → Phrase → Code

In collaboration with the development team, I defined a consistent naming convention. Keys were created and maintained by designers in context, enabling a seamless design-to-development workflow and significantly reducing developer time spent searching for the correct key-value pairs.

Business Impact

⏱️ Task completion time dropped from 12 mins 29seconds to 6 seconds for critical flows (e.g. finding Shipment note number)

Stakeholder Impact

👥 8000+ users onboarded across plants of 6 brands (Audi, SEAT, Skania, Porsche, VW, Skoda) with consistently positive adoption feedback

Organisational Impact

📜 As a new standard

The user insights and customer journey we explored and defined have since been adopted by other teams as organizational UX standards.

All Rights Reserved

Note: All data is mock and does not represent real production figures. Confidential details have been removed.

Volkswagen Group

Orchestrating Complexity: VW Supply Chain

Control Center

Product Format: Web application (Responsive)

Project Year: 2022 – Present

Business Partner: VW Group Procurement

What if enterprise tools were as intuitive as the apps we use every day — no matter how complex the workflow or data?

Field research & user workshop

To gather diverse insights, we intentionally brought in 10 users from different environment and knowledge level.

We asked multiple questions about their daily process and digital and physical touch points in identifying part situation and shadowed their daily work over three days. Afterwards, we sat down and mapped their work processes and visualised the stakeholder map in Miro.

Stakeholder mapping

Focus Area: “Problem Detection”

Challenge & Opportunities

Challenge 1

Cognitive Overload: All information on one page creates distraction and prevents effective shortage identification

Challenge 2

Tool Carnivalism: Disconnected systems for shortage identification, problem solving, and reporting create silos and internal cannibalization

Challenge 3

Supply Chain Blind Spots: Missing external supplier information and tier relations obscure 80% of shortage root causes

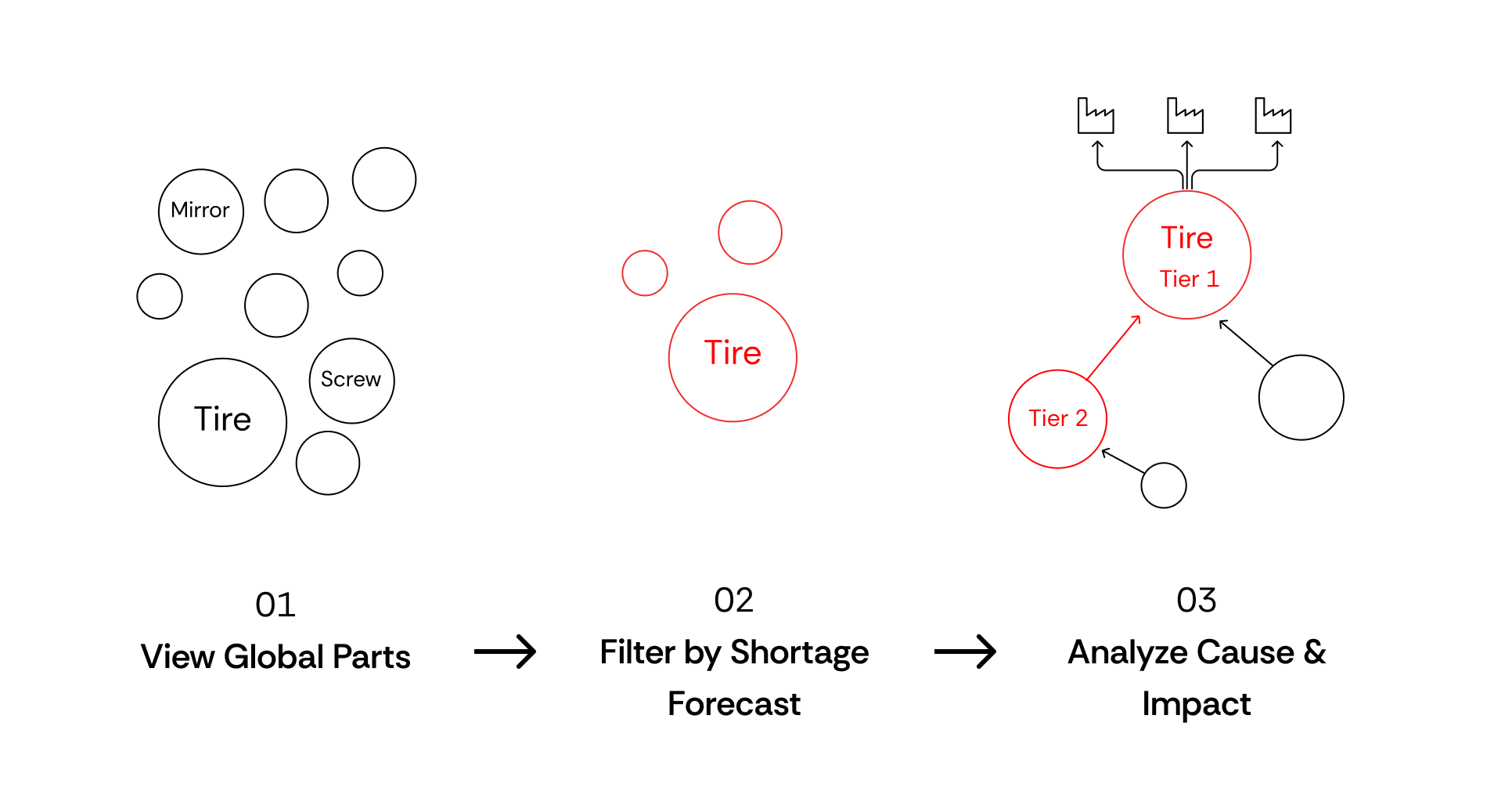

Opportunity 1

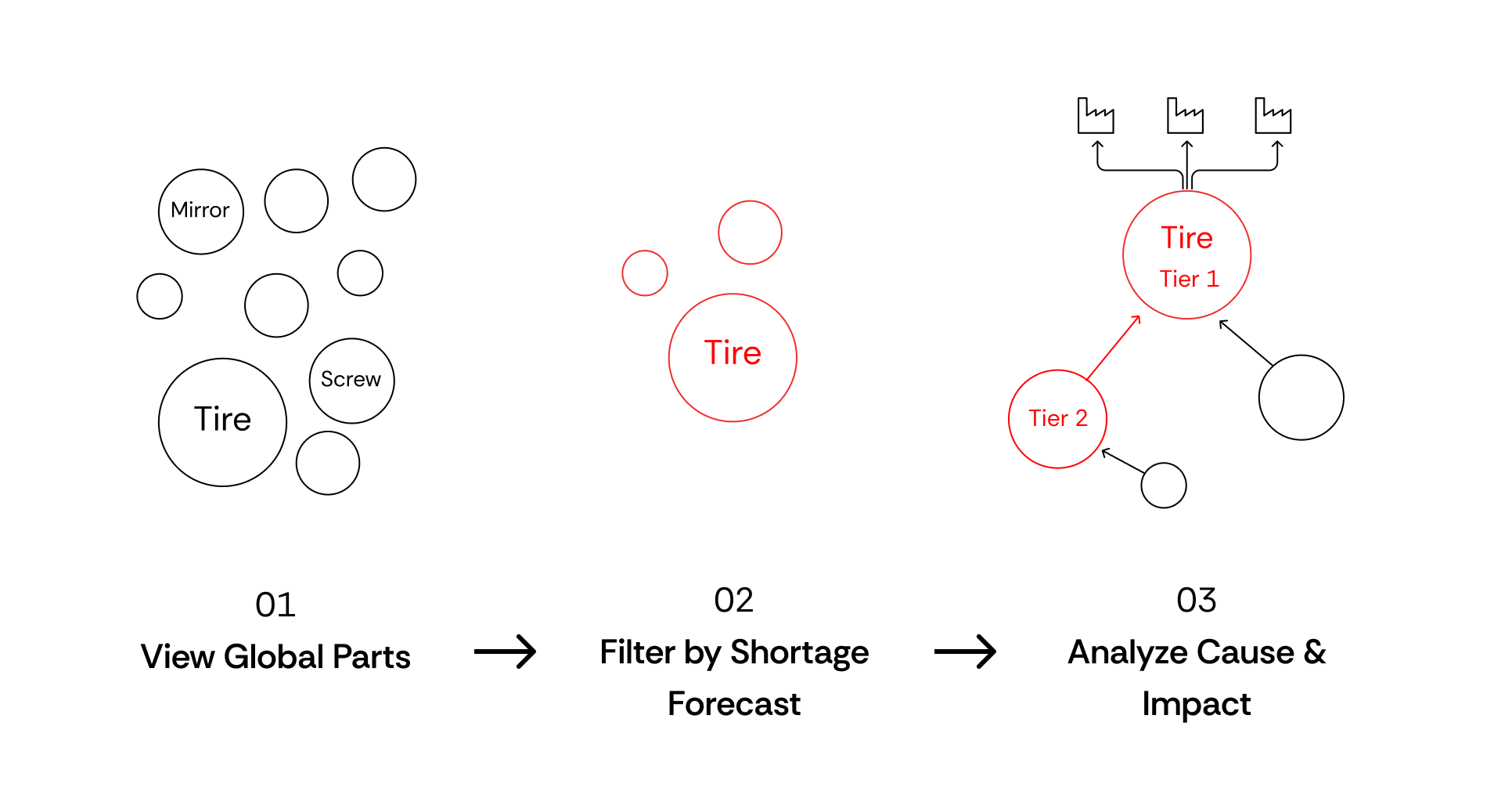

Staged Information Diet: Divide workflow into three digestible pages—Global overview, Part details, and Bottleneck management

Opportunity 2

Ecosystem Orchestration: Provide API bridges to specialized tools instead of building everything, enabling seamless cross-platform workflows

Opportunity 3

N-tier Graph: Use graph visualization to reveal hidden part-specific supply chain relationships with BOM data

Figma → Phrase → Code

In collaboration with the development team, I defined a consistent naming convention. Keys were created and maintained by designers in context, enabling a seamless design-to-development workflow and significantly reducing developer time spent searching for the correct key-value pairs.

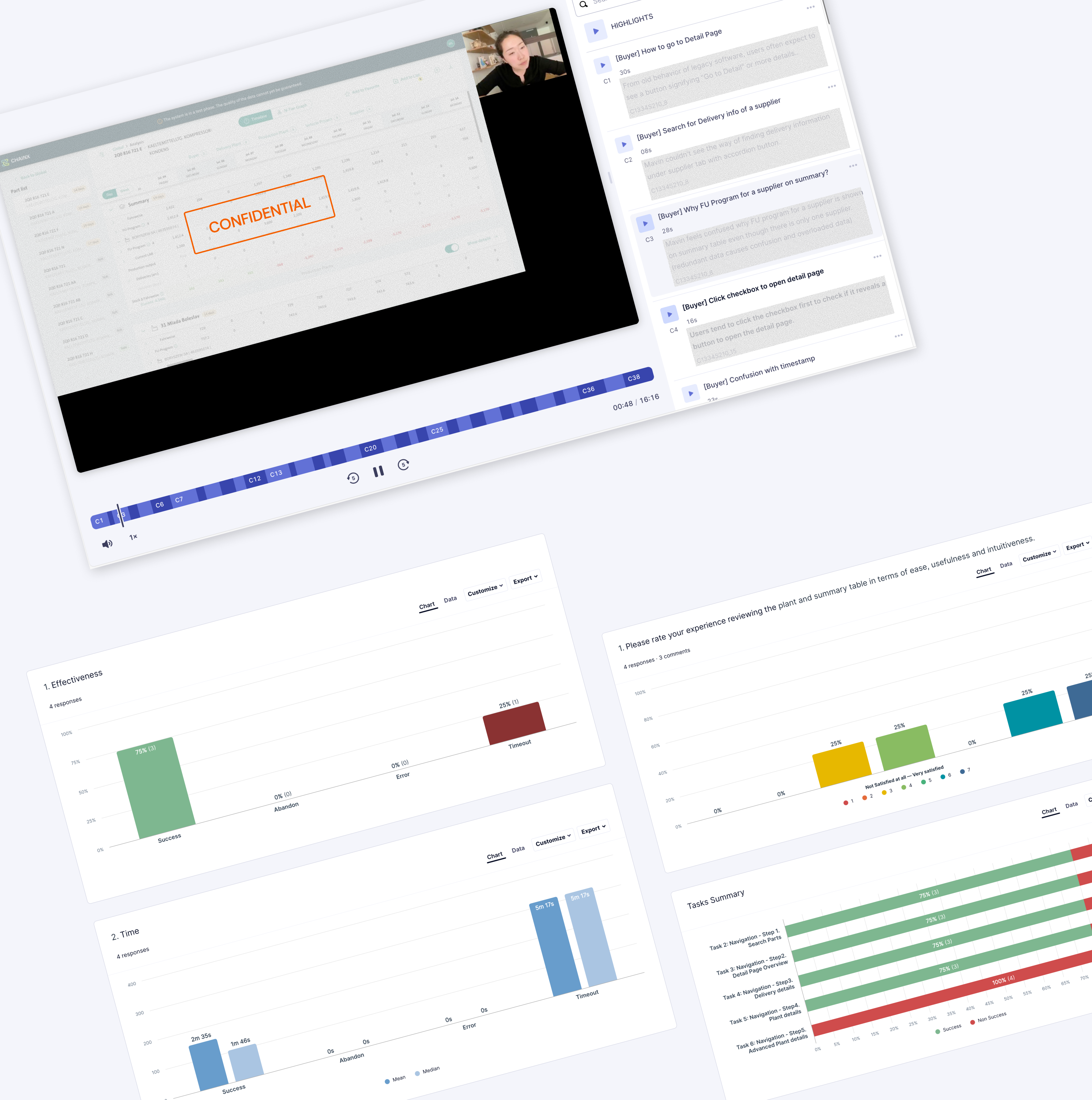

Business Impact

⏱️ Task completion time dropped from 12 mins 29seconds to 6 seconds for critical flows (e.g. finding Shipment note number)

Stakeholder Impact

👥 8000+ users onboarded across plants of 6 brands (Audi, SEAT, Skania, Porsche, VW, Skoda) with consistently positive adoption feedback

Organisational Impact

📜 As a new standard

The user insights and customer journey we explored and defined have since been adopted by other teams as organizational UX standards.

“

I didn't think a tool like this could exist here. It feels like it was made by someone who actually understands my day.

All Rights Reserved

Note: All data is mock and does not represent real production figures. Confidential details have been removed.

Volkswagen Group

Orchestrating Complexity: VW Supply Chain

Control Center

Product Format: Web application (Responsive)

Project Year: 2022 – Present

Business Partner: VW Group Procurement

What if enterprise tools were as intuitive as the apps we use every day — no matter how complex the workflow or data?

Field research & user workshop

To gather diverse insights, we intentionally brought in 10 users from different environment and knowledge level.

We asked multiple questions about their daily process and digital and physical touch points in identifying part situation and shadowed their daily work over three days. Afterwards, we sat down and mapped their work processes and visualised the stakeholder map in Miro.

Stakeholder mapping

Focus Area: “Problem Detection”

Challenge & Opportunities

Challenge 1

Cognitive Overload: All information on one page creates distraction and prevents effective shortage identification

Challenge 2

Tool Carnivalism: Disconnected systems for shortage identification, problem solving, and reporting create silos and internal cannibalization

Challenge 3

Supply Chain Blind Spots: Missing external supplier information and tier relations obscure 80% of shortage root causes

Opportunity 1

Staged Information Diet: Divide workflow into three digestible pages—Global overview, Part details, and Bottleneck management

Opportunity 2

Ecosystem Orchestration: Provide API bridges to specialized tools instead of building everything, enabling seamless cross-platform workflows

Opportunity 3

N-tier Graph: Use graph visualization to reveal hidden part-specific supply chain relationships with BOM data

Figma → Phrase → Code

In collaboration with the development team, I defined a consistent naming convention. Keys were created and maintained by designers in context, enabling a seamless design-to-development workflow and significantly reducing developer time spent searching for the correct key-value pairs.

Business Impact

⏱️ Task completion time dropped from 12 mins 29seconds to 6 seconds for critical flows (e.g. finding Shipment note number)

Stakeholder Impact

👥 8000+ users onboarded across plants of 6 brands (Audi, SEAT, Skania, Porsche, VW, Skoda) with consistently positive adoption feedback

Organisational Impact

📜 As a new standard

The user insights and customer journey we explored and defined have since been adopted by other teams as organizational UX standards.

“

I didn't think a tool like this could exist here. It feels like it was made by someone who actually understands my day.

All Rights Reserved